PPS and Ryton® Coating

Chemical resistance at high temperatures

Chemical resistance in a thin-film form

Benefits of PPS and Ryton® Coatings:

- Non-stick

- Low Coefficient of Friction

- Abrasion Resistance

- Heat Resistance

- Chemical Resistance

PPS and Ryton® Coating – Chemical resistance at high temperatures

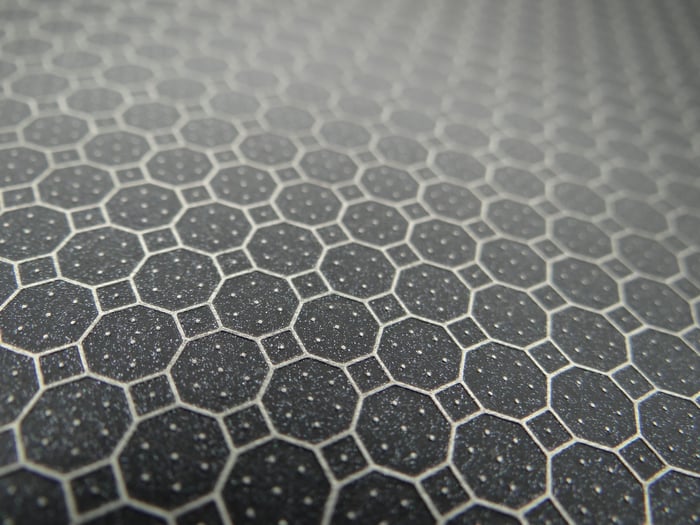

PPS (polyphenylene sulfide)/Ryton® is a resin bonded polymer coating with outstanding resistance to chemical reactivity and thermal degradation. This coating is virtually unaffected by any solvent to 500°F, making it a popular alternative for use in the chemical processing industry. PPS coatings may be used by themselves for excellent corrosion and chemical resistance, and also function as an effective primer with the use of a top coat. In addition to its thermal and chemical advantages, PPS also offers excellent abrasion and wear resistance.

Have questions on the use of PPS and Ryton coatings in your application? Talk to a Toefco PPS and Ryton industrial coating engineer today by using our contact form below.

Our Industrial

Coating Services

Teflon™ expert

application of the popular

fluoropolymer family

Excalibur Coating exclusive

nonstick with superior

adhesion

Xylan thin film coating for

friction control

Fluoropolymer time-tested

resin/lubricant blend

Nitrocoat hardness and

friction protection at

extreme temperatures

Molybdenum Disulfide

fights friction in high

pressure loads

Epoxy Thermal Cure

corrosion and abrasion

protection with impact

resistance

PTFE the gold standard

for nonstick coating

PPS/Ryton chemical

resistance in a thin-film form

FEP PTFE performance

with greater abrasion

resistance

PVDF top quality for

chemical processing

ECTFE impact strength

plus chemical resistance

ETFE strong corrosion

protection across

temperature ranges